管理半成品¶

A semi-finished product, also known as a subassembly, is a manufactured product that is used as a component in another product’s bill of materials (BoM). Semi-finished products are used to simplify complex BoMs or to more accurately represent a manufacturing flow. A BoM that contains semi-finished products is referred to as a multilevel BoM, where the main top-level product and its subassemblies are distinguished.

Configure semi-finished products¶

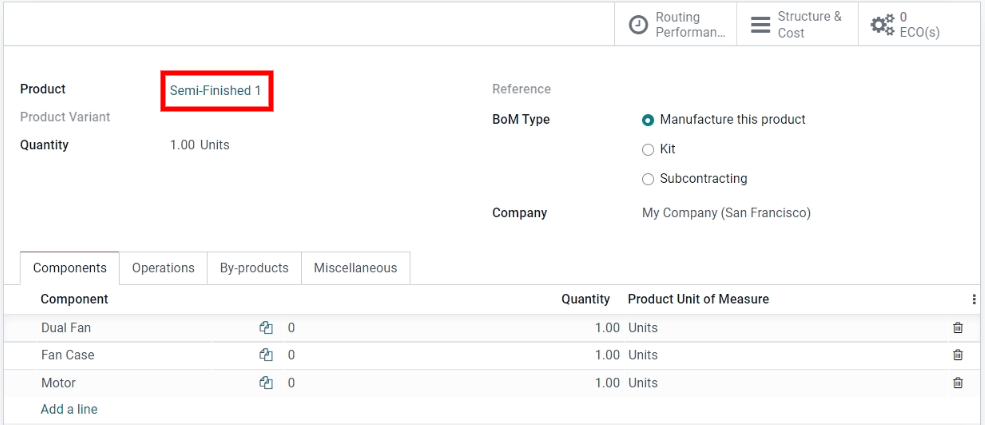

To set up a multilevel BoM, the top-level product and semi-finished products must be configured. Therefore, the first step is to create the semi-finished products and their BoMs.

参见

Create the top-level bill of materials (BoM)¶

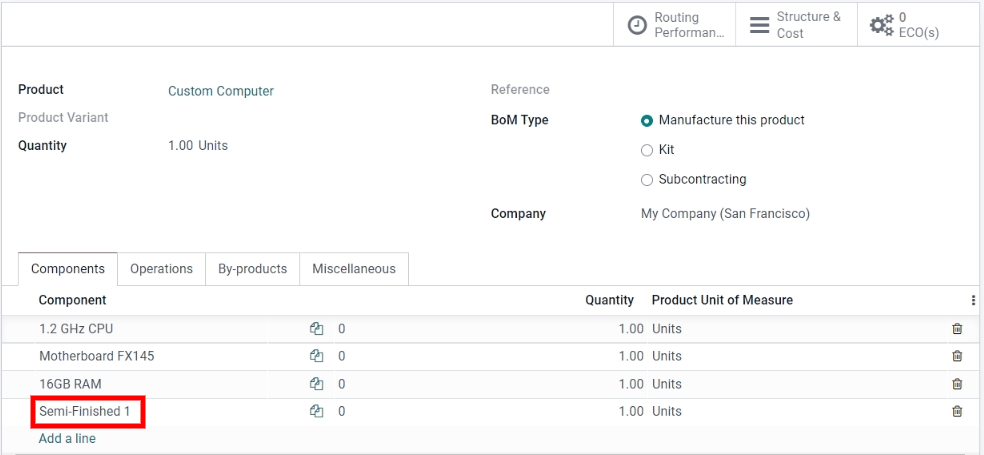

After the semi-finished products are fully configured, navigate to . Then, Create the top-level product. Configure the product’s specifications as desired, and be sure to Save.

Once the top-level product is configured, click the Bill of Materials smart button on the product form, then click Create to make a BoM for the top-level product. Then, simply add the semi-finished products to this BoM, along with any other necessary components.

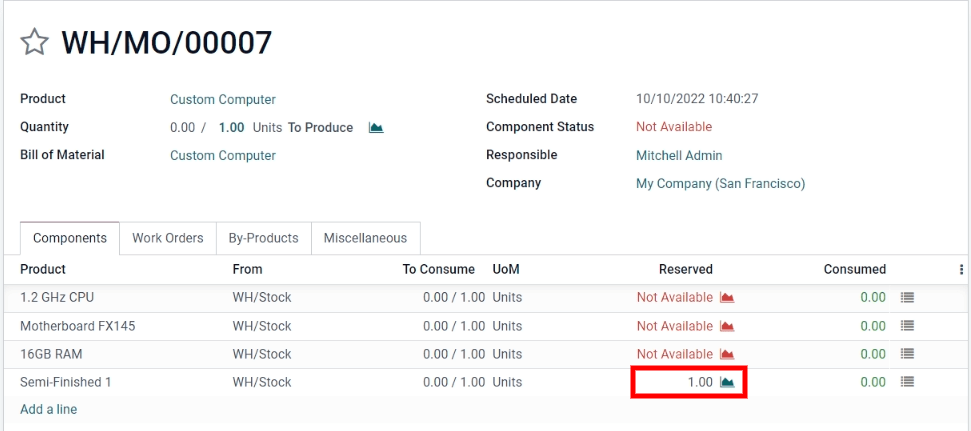

Manage production planning¶

There are several methods to manage manufacturing order automation for products with multilevel BoMs.

注解

Semi-finished products are specifically used to manage manufacturable products with multilevel BoMs. If a BoM is being created simply to organize components or bundle sellable products, using Kits is the more appropriate option.

To automatically trigger manufacturing orders for semi-finished products after confirming a manufacturing order for the main product, there are two options:

Option 1 (recommended): Create Reordering Rules for the semi-finished products and set both the minimum and maximum desired stock quantities to

0.

参见

** 选项 2:** 在半成品产品表单的 库存 标签下激活 按订单补货(MTO) 和 制造 路线。

选项1比选项2更灵活,因此推荐使用。安全库存策略不直接将需求与补给联系起来,因此在必要时允许库存未预留并重定向到其他订单。The Replenish on Order(MTO)路线在半成品和顶级产品之间创建了一个独特的链接,专门为已确认的顶级制造订单预留数量。

Regardless of the method chosen, semi-finished products must be fully manufactured before manufacturing can begin on the top-level product.